When it comes to modern car manufacturing, the utilization of sustainable materials is more than just a trend—it’s a strategic shift towards a greener automotive landscape. Imagine a world where cars are not only efficient and stylish but also leave a significantly smaller ecological footprint. The incorporation of sustainable materials is reshaping the way vehicles are built, paving the way for a more environmentally conscious industry. But how exactly are these materials transforming the future of car manufacturing?

The Environmental Impact of Traditional Materials

When manufacturing cars, traditional materials like steel and aluminum contribute significantly to environmental impact. The extraction of these materials requires extensive energy consumption, leading to greenhouse gas emissions. Additionally, the manufacturing process of steel and aluminum involves chemical treatments and high temperatures, further increasing their environmental footprint. As a consumer, it’s essential to consider the full life cycle of a product, including the materials used in its production.

Furthermore, the transportation of raw materials and parts for traditional car manufacturing involves burning fossil fuels, adding to air pollution and carbon emissions. The disposal of vehicles at the end of their life also poses environmental challenges, as steel and aluminum can take a long time to decompose and may release harmful substances into the environment. By understanding the environmental impact of traditional materials, you can make more informed decisions when choosing a vehicle and support the shift towards sustainable materials in the automotive industry.

Advantages of Using Sustainable Materials

Using sustainable materials in car manufacturing offers numerous benefits that extend beyond environmental considerations. By incorporating sustainable materials such as recycled plastics, natural fibers, and bio-based composites, car manufacturers can reduce their carbon footprint and decrease reliance on finite resources. These materials often weigh less than traditional ones, leading to improved fuel efficiency and reduced emissions during the vehicle’s operational lifespan. Additionally, sustainable materials can enhance the overall durability and strength of car components, contributing to longer product lifecycles and potentially lowering maintenance costs for consumers.

Choosing sustainable materials also fosters innovation within the automotive industry, encouraging the development of new technologies and processes that align with eco-friendly practices. Furthermore, utilizing these materials can help companies meet evolving consumer demands for environmentally conscious products, potentially attracting a wider customer base.

Innovative Applications in Car Manufacturing

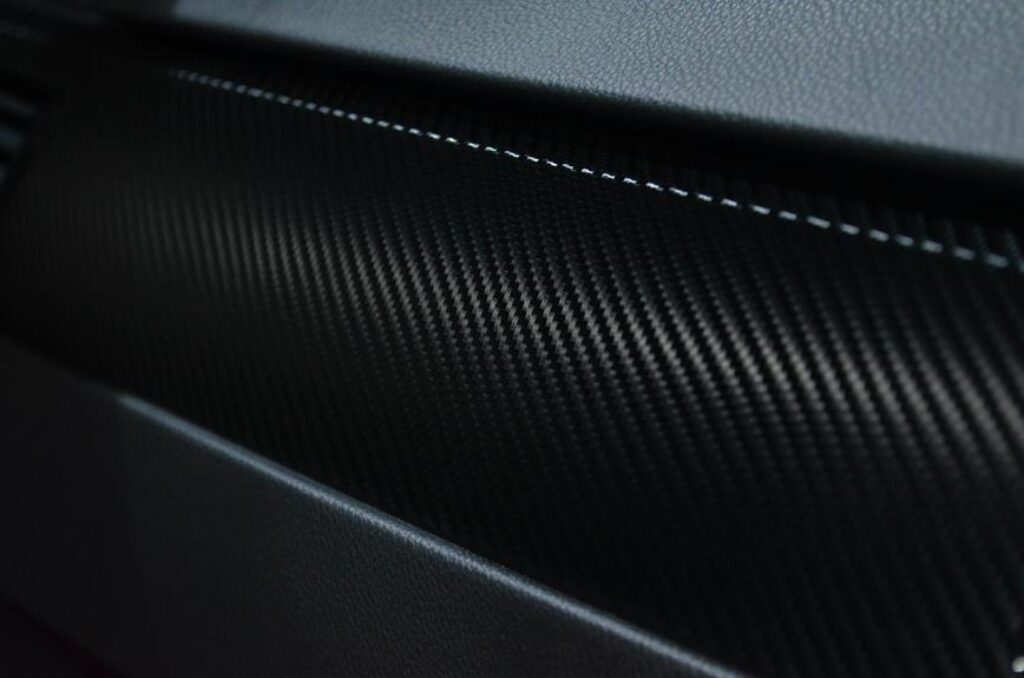

Sustainable materials are driving innovation in car manufacturing through their unique applications and transformative impact on the industry. Manufacturers are increasingly incorporating materials like recycled plastics, bamboo, and even algae into the production of cars. These materials offer a range of benefits, including reduced weight, improved fuel efficiency, and lower carbon emissions. For example, recycled plastics can be used in interior components, reducing the environmental footprint of the vehicle while maintaining quality and durability.

Another innovative application is the use of natural fibers like hemp and kenaf in car panels, providing a lightweight and eco-friendly alternative to traditional materials. These natural fibers offer comparable strength to traditional materials like fiberglass, making them a sustainable choice for car manufacturing. Additionally, companies are exploring the use of biodegradable materials in certain components, further enhancing the sustainability of cars.

Future Trends and Challenges

Looking ahead to the future of car manufacturing, industry experts anticipate a shift towards cutting-edge technologies and a heightened focus on sustainability practices. One key trend is the increasing integration of renewable energy sources in the manufacturing process, such as solar panels to power production facilities. This shift not only reduces the carbon footprint of manufacturing but also lowers operational costs in the long run.

Additionally, advancements in materials science are paving the way for the development of new sustainable materials that are lightweight, durable, and recyclable. Car manufacturers are exploring alternatives to traditional materials like steel and aluminum, opting for bio-based composites and recycled plastics.

However, along with these exciting developments, challenges lie ahead. One major hurdle is the need for standardized regulations and certifications for sustainable materials to ensure consistency and quality across the industry. Another challenge is the cost associated with implementing these new technologies and materials on a large scale. Finding ways to make sustainable practices financially viable without compromising quality will be crucial for the future of car manufacturing.

Automotive & Tools